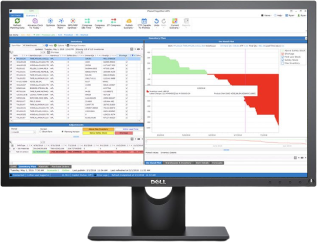

APS

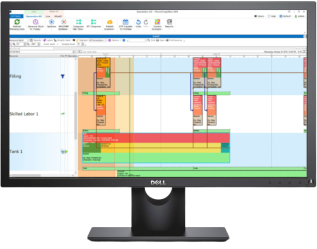

MES

APS sends optimized schedules to MES for precise execution, while MES provides real-time feedback to APS for continuous improvements

Explore how we can solve these challenges

APS sends optimized schedules to MES for precise execution, while MES provides real-time feedback to APS for continuous improvements

ERP manages data, but it doesn’t optimize your production. Learn how APS fills the gap with real-time scheduling, bottleneck prevention, and adaptive planning.

Manual scheduling tools and outdated methods lead to inefficiencies, unnecessary changeovers, delays, and high costs. Here’s what might be holding you back:

From minimizing disruptions to optimizing resource allocation, PlanetTogether APS addresses real-world manufacturing challenges effectively

PlanetTogether APS tackles each stage of the manufacturing value chain, from raw materials to final delivery, with advanced features that provide real-time adaptability, visibility, and control over every production variable.

$16M annual savings and 6% unit cost reduction.

“Scheduling decisions are now based on KPIs, not intuition.”

Streamlined operations across 33 production lines.

“Scheduling inefficiencies are now a thing of the past.”

50% reduction in data entry time.

“From spreadsheets to smart factory scheduling, APS transformed us.”

“The shift to PlanetTogether is saving us about 15

percent in inventory overhead and about 20 percent in

overtime labor expenses. We’re not building equipment

to stock any longer—we’re building to ship!”

Director of Manufacturing,

DePuy Synthes, a Johnson & Johnson Company

Most clients implement the system within weeks and see immediate improvements in scheduling efficiency and production visibility.

Absolutely, with our SuperPlant™ feature, you can synchronize schedules across all locations.

Yes, PlanetTogether APS integrates seamlessly, replacing manual scheduling tools.

Most clients see measurable improvements within one year, including cost savings and delivery performance.

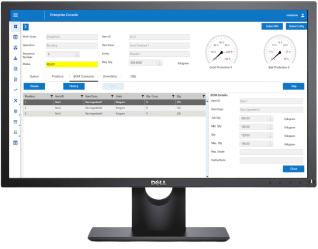

APS is a “data-intensive” tool requiring the right information to be accurate. Fortunately, most companies already have 99% of the data needed to get started and you can improve it over time. One benefit of an APS system is that it provides an incentive to clean-up and standardize data that was previously under-utilized and somewhat neglected.

You’ll need routings and bills-of-material for discrete manufacturers or formulas and run-rates for process-manufacturers. For inventory-constrained scheduling, it’s also important to have a reliable inventory control process with accurate on-hand quantities. Also, if you follow a daily planning cycle, you’ll need to track production completions daily, as well; if weekly, then production updates can be tracked weekly.

While rough-cut infinite capacity planning is useful for planning labor and capacity levels long-term, most manufacturers find it far more value to use finite constraint-based planning. Unless you plan to schedule a very low volume of production orders (maybe 25) and can manually make drag-and-drop adjustments, finite scheduling will deliver many benefits infinite planning will not. Even if you have enough capacity on average, there are likely “clumps” of workload that will create temporary bottlenecks. Finite scheduling gives you the insight of where and when theses bottlenecks will occur. And you understand the impact of these changes on the order schedule, which enables you to produce detailed, actionable plans that invariably save valuable time on the shop floor and planning department.

ERP systems are ideal in managing transactions, like order entry or inventory control. ERP evolved from accounting systems to keep track of what has happened versus planning for what is going to happen. As a result, the architecture is optimized for transaction processing rather than large-scale, high-volume data analytics. Consider a typical MRP re-gen can take hours or days while an APS re-gen usually takes a few seconds. This is a critical usability factor because no planner can afford to wait hours, let alone days, after every schedule change.

Better still, the design and development expertise in an APS system is unique and specialized, and hard to come by. Most ERP development projects leave planning as an afterthought and only address it superficially. APS is all about the details. That’s why most “classic” scheduling in ERP systems goes unused; it is too simplistic to affect real improvement. APS solves critical problems and drives productivity.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

ERP systems are great for managing data, but they don’t optimize your scheduling. Discover how Advanced Planning & Scheduling (APS) bridges the gap with real-time scheduling, automation, and efficiency improvements.

Learn how to overcome inefficiencies and optimise production with our FREE guide. Let’s get started!

Get a personalized walkthrough of how APS can optimize your operations and deliver measurable results.